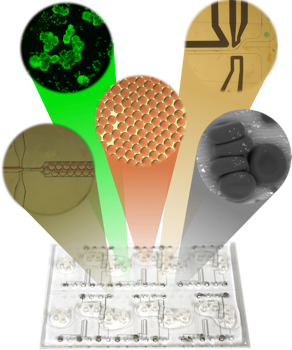

Microbeads synthesis

Microfluidic for Biomaterial synthesis

The future viability of Australia’s chemical manufacturing industry depends on science and technology that can be exploited to generate more elaborately transformed materials. There has been great effort in in developing such materials since the last few decades (e.g. new nanoparticles and new biomaterials). However, the main bottle-neck for some of the developments is the need for screening ‘libraries’ of massive numbers (up to 1012) of candidate chemicals, biological and synthesis parameters. This could cost up to millions to billions and take several years to complete, even using the state of the art high throughput screening facilities.

The CSIRO Fluid Dynamics Group addresses this challenge by using droplet-based microfluidic technologies. Water in oil emulsion droplets are generated in microfluidic devices and act as compartmentalised picolitre reactors. These devices use millilitre samples to generate millions of microdroplets, i.e. reactions, within a few hours, unprecedented speed and low cost for developing new materials.

We have developed droplet lab on a chip platforms that are able to generate millions of monodispersed microdroplets (single or double emulsions) with very high throughput (up to ~103 drops/s), fuse droplets on the fly for adding reactants, perform chemical and biological synthesis in individual droplets, detect droplet and select droplets for desirable products. We have demonstrated synthesis of green florescence protein and OpdA enzyme molecules, the latter laying the foundation for evolving the enzyme for desired property. In addition to synthetic biology, we also applied the technique for nanomaterials synthesis, e.g., production of microbeads from various biomaterials (synthetic or natural hydrogels, peptides, and polymers); or the manipulation of Metal Organic Framework (MOF) inside microchannels.

Tuesday, 17 September 2013